We scour the world looking for materials that make better products.

Bradford brings added value through our use of proprietary materials which are cleaner and stronger yet softer and less abrasive than industry standards. We protect our customers’ products — and their reputations — with the best made interior protective packaging.

We’ve developed foams that cushion to hold parts firmly, and foams which absorb energy and dampen shock. We create textiles that weigh less, wear longer, and provide a soft cradle for your parts. We often redeploy, rather than add to, the materials in standard packaging for improved performance and increased throughput for lineside operators.

We are different than the competition. We do more than design and build great packaging and material handling systems – we design and create the materials that give our customers a true advantage in the marketplace.

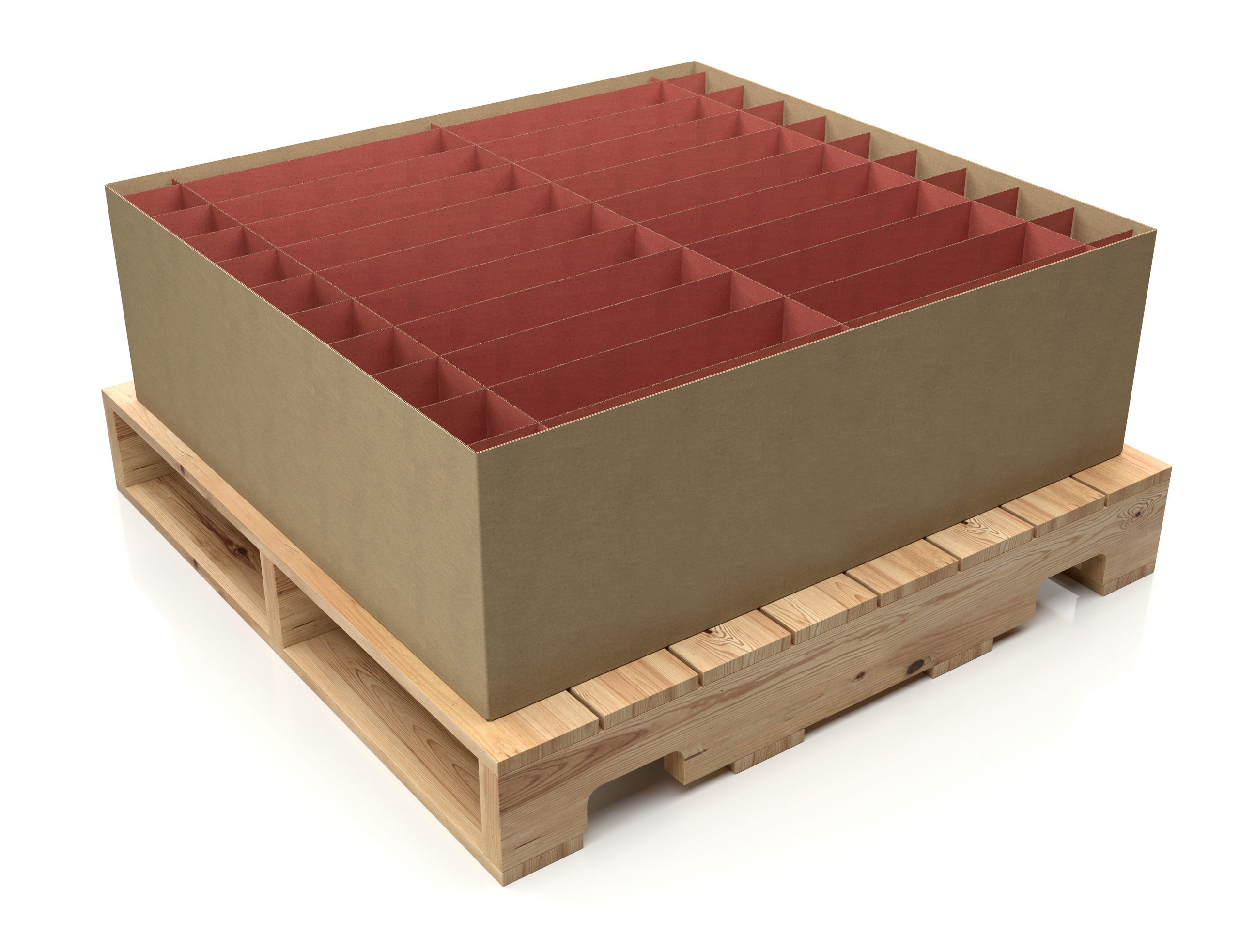

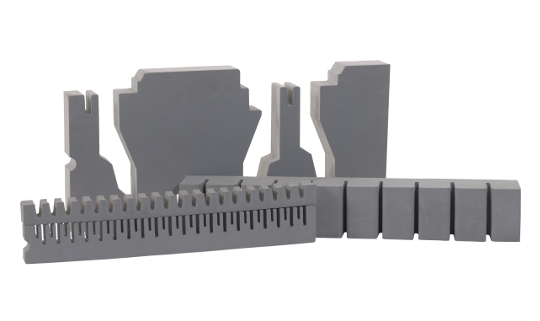

Paperboard

Bradford Company has designed and manufactured protective paperboard packaging products since 1924. This experience, supported by leading edge technology and delivered with exceptional customer service, ensures the integrity of your products during every shipment.

Only Bradford offers a complete package of advantages, including:

- quick turnaround on quotations and samples

- custom, creative solutions

- prompt, on-time delivery, every time

- no minimum order quantities

- testing and validation

The Bradford customer service team is your partner in paperboard packaging. We understand your expectations and go above and beyond to exceed them. Our testing and design validation services help you meet your targets and move your project forward with confidence. Bradford custom machinery and equipment make paperboard and chipboard packaging from a wide range of materials, for satisfied customers worldwide.

Corrugated

In addition to our expertise in paperboard, Bradford Company can design, produce, and assemble packaging solutions using corrugated materials. Whether a single or a double-wall design, a packaging solution utilizing corrugated construction can offer the protection your product needs while reducing abrasion incidents and increasing stack strength.

- Single wall

- Double wall

- Uncoated/kraft

- Anti-abrasive – Nomar and Andersoft

- Stock Cutouts and finger notches

- Plastic Corrugated

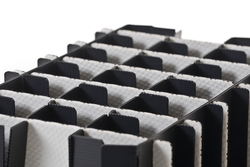

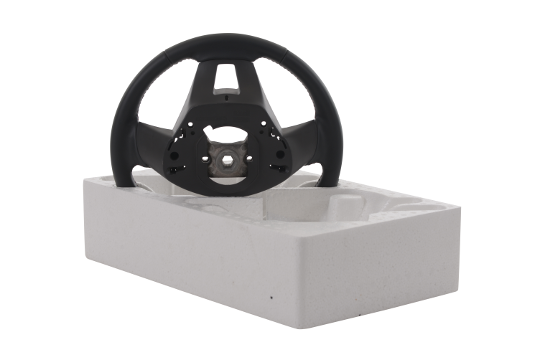

Softedge®

Softedge was developed in response to our customers’ ever increasing demand for outstanding part protection and most importantly, to offer a user friendly partition material. Softedge delivers both. Our unique manufacturing process marries soft & durable partition substrates with the excellence in dunnage design that customers have come to expect from Bradford.

Softedge is the perfect choice for any partition that protects a class “A” surface or decorative part. Lineside operators favor Softedge over conventional partition materials because it is ergonomically superior and “easy on the fingers.” The promise of fewer damaged parts and fewer reportable injuries makes Softedge the #1 choice for many applications. Additionally, partitions made with Bradford Softedge may allow for greater part density and lowered logistics costs as a result.

Our customers have reported outstanding results when packaging many different products in Softedge including:

• Painted Door Handles

• Painted Mirror Assemblies

• Chrome Trim & Badges

• Console Bezels

• Headlamps

• Tail Lamps

• Lenses

• Other Sensitive Class “A” Parts

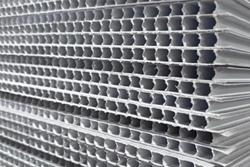

Polylite®

Polylite® is an extruded polypropylene foam with a smooth surface that provides excellent impact resistance and is ideal for protecting parts from abrasion damage. This material is exclusively distributed by Bradford Company in North America and is stocked in various grades, weights, and thicknesses. Polylite® is completely recyclable.

Polylite® has no flutes to trap moisture or contaminants and unlike plastic corrugated there is uniform strength across the sheet – and no “wash board” effect created by ribs.

Polylite® weighs only 30% of conventional polypropylene sheet stock and it can be formed into light weight containers and interior packaging that will give you years of service.

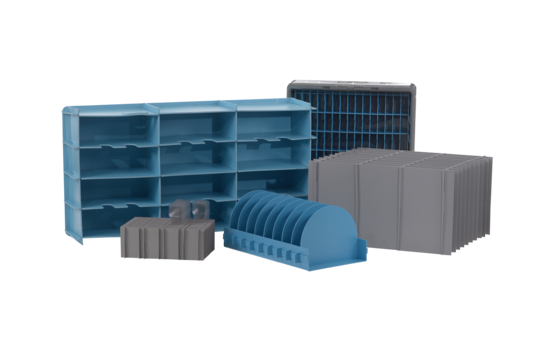

Plastic

Bradford stocks a wide selection of plastic corrugated material to ensure our customers’ needs are fully met or exceeded. In partnership with the mills, Bradford leads the way with innovative plastic materials and customized applications of the latest plastics packaging manufacturing technologies.

Fabrics/Textiles

Bradford Company is the Packaging Industry leader in applied development and use of textiles. Bradford holds numerous design patents on fabric dunnage systems and unique textile applications for product protection. Sophisticated sewing capability and a comprehensive offering of specialty textiles provide many options from which to choose. Numerous fabrics, laminated to a wide variety of substrates, further enhance Bradford Company’s ability to satisfy every requirement for handling and shipping sensitive parts.

A large selection of textiles are in-stock at all times, including light-weight non-wovens, brushed polyesters, and PVC fabrics.

Foam

Bradford works with a variety of foam materials, utilizing our expertise to select just the right design and material to meet a wide variety of stringent requirements. Whether you are packing parts “hot off the press” or shipping products that are “fragile as eggs”, our Design and Manufacturing teams provide solutions that protect your most sensitive products from the ravages of transportation and storage environments. Bradford’s multinational operating structure assures you that we understand the rigors of both domestic and international transportation modes.