The material, simple. The design, brilliant. Your product, protected.

Bradford Company has designed and manufactured protective paperboard packaging products since 1924. This experience, supported by leading edge technology and delivered with exceptional customer service, ensures the integrity of your products during every shipment.

Get a Quote

Only Bradford offers a complete package of advantages, including:

- quick turnaround on quotations and samples

- custom, creative packing solutions

- prompt, on-time delivery, every time

- no minimum order quantities

- testing and validation

The Bradford customer service team is your partner in paperboard packaging. We understand your expectations and go above and beyond to exceed them. Our testing and design validation services help you meet your targets and move your project forward with confidence. Bradford custom machinery and equipment make paperboard and chipboard packaging from a wide range of materials, for satisfied customers worldwide.

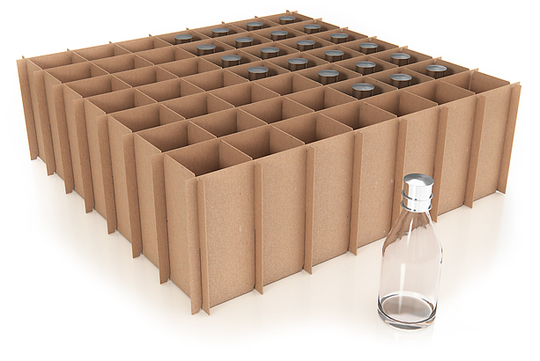

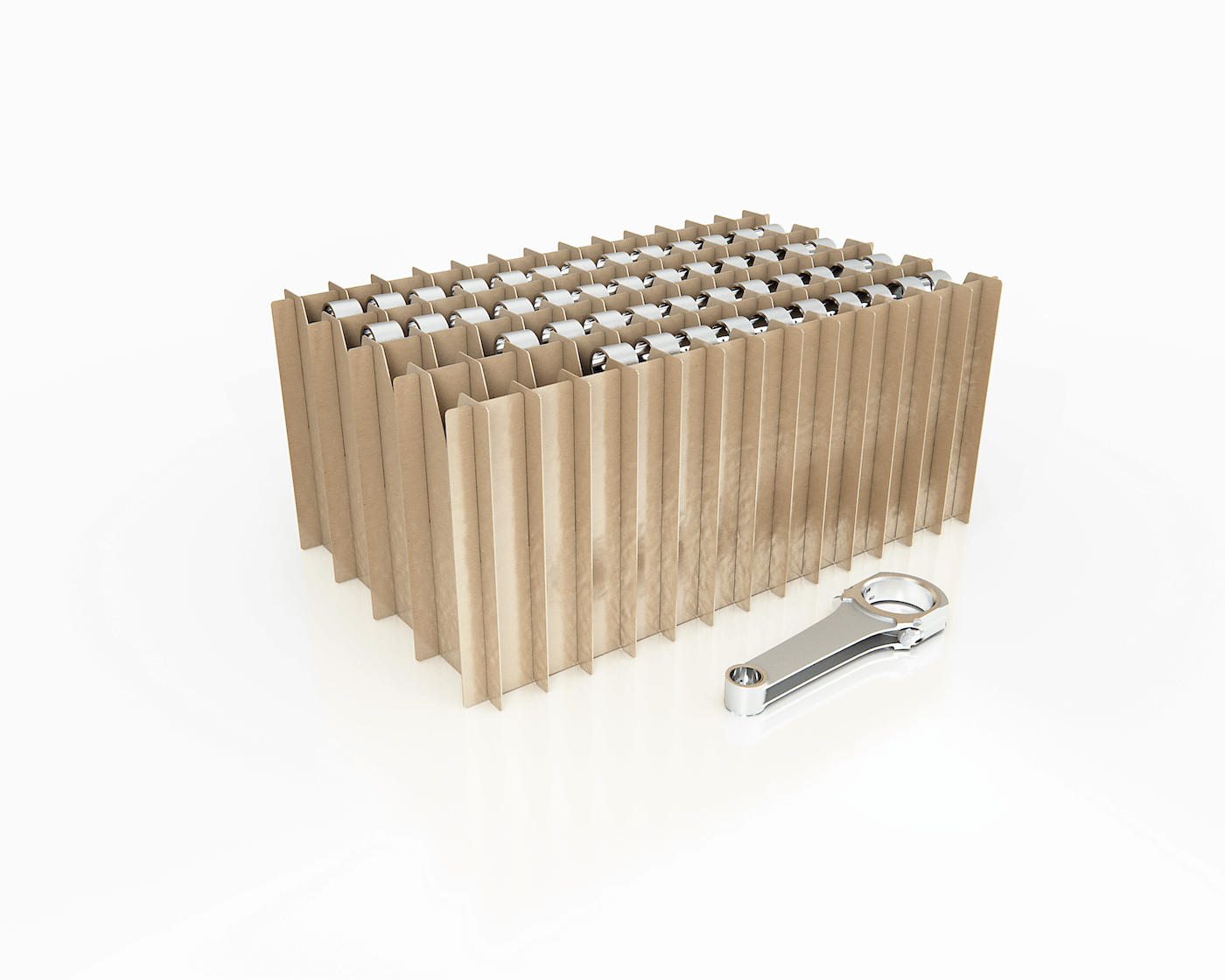

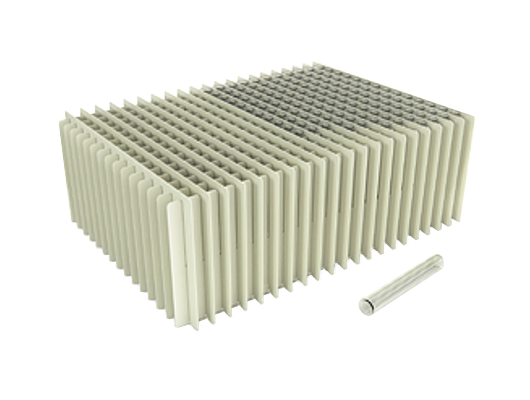

Chipboard Partitions

Bradford Company chipboard partitions can be used to protect both large and small parts and are especially adaptable for the packaging of unusual shapes. We would be happy to design and sample a custom partition based on your specifications, parts, or math data.

At Bradford, we use extensive experience and CAD programs to provide a design that protects your products and improves density in your containers, pallets, trucks and warehouses—all of which translates into significant savings. We offer dozens of grades, thicknesses, and paperboard/chipboard materials to suit every packaging application. Eliminate the cost of bagging or foam with Bradford laminations and coatings.

Chipboard packaging advantages:

- less expensive and cleaner than corrugated

- lighter and thinner (requires less floor space)

- made from recycled cardboard and paperboard

- 100% recyclable

- better density than corrugated

- stocked in rolls and sheets for just-in-time shipping

- a wide range and variety of calipers from .020 to .176

Chipboard partitions are ideal for:

- automotive, pharmaceutical, glass, cosmetics, and other industrial packing applications

- trays

- pads

- partition dividers

ENV-3000™ Ultrasmooth Chipboard Partitions

The exceptionally smooth finish on Bradford ENV-3000® specialty protective packaging makes it a step up from regular chipboard. This provides excellent resistance to abrasion and scuffing. The smooth finish is accomplished in the manufacturing process, with no special coatings subsequently applied.

ENV-3000 advantages

- recyclable

- ultra-smooth finish

- excellent resistance to abrasion and scuffing

- cost-saving alternative to polycoated chipboard/paperboard

- in stock for just-in-time shipping

ENV-3000 is ideal for

- automotive, appliance, and class A parts partition dividers

Polycoated Chipboard Partitions

Bradford high quality polycoated chipboard and paperboard feature a thin coating of low density polyethylene on both sides of the board.

Polycoated chipboard makes great protective packaging for automotive, appliance, and other painted/chromed or sensitive parts.

Polycoated advantages

- Class A protectant for customer-visible surfaces

- protection against abrasion and scuffing

- moisture resistant

- cost-saving alternative to labor-intensive bagging and/or masking

- a wide range of in-stock calipers from .018–.080

XDS-1000

This material has a very durable, puncture-resistant surface. The surface will outperform most other plastic materials for wear durability. It is a great low-cost alternative to plastic partitions.

XDS-1000 Advantages

- Surface durability

- Puncture/wear-resistant surface

- In stock with short lead time

- Cost-saving alternative to plastic materials

- Recyclable

FabriKraft®

Bradford’s exclusive FabriKraft® specialty paperboard provides the most effective protective packaging for parts with highly sensitive finishes. This high quality paperboard base is laminated with a spun-bonded polyolefin, providing exceptional protection against abrasion and scuffing. FabriKraft® is made with the same technology used to produce eyeglass lens wipes.

FabriKraft® advantages

- laminated with a spun-bonded polyolefin

- exceptional protection against abrasion and scuffing

- available in fabric on one or two sides, or in strips, based on your requirements

FabriKraft® is ideal for

- highly sensitive parts, such as chrome, soft-touch lenses, and wood grain

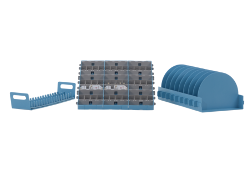

SBS and Polymilk Chipboard Partitions

Bradford SBS and polymilk chipboard is made from fully bleached virgin fiber that results in a clean, solid white product—not just a colored top coating. The surface is smoother, making it conducive for high quality printing. The chemical formulation resists tarnishing, and because of its higher density, SBS and polymilk cut cleaner to make great looking dividers for retail, pharmaceutical and consumer products.

SBS paperboard and polymilk advantages

- smoother, cleaner surface

- conducive for high quality printing

- chemical formulation resists tarnishing

- cuts cleanly due to its higher density

SBS paperboard and polymilk are ideal for

- printed packaging

- consumer packaging such as retail, pharmaceutical

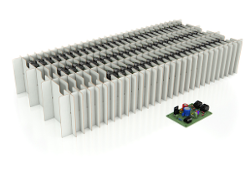

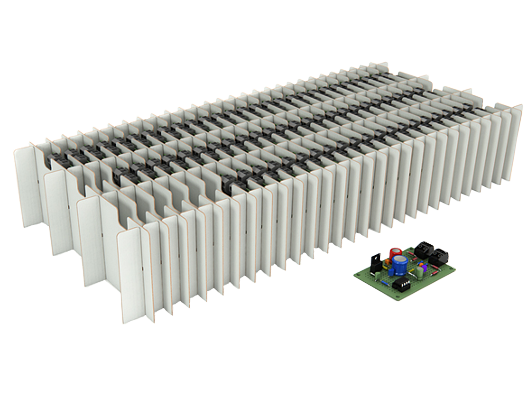

Strata-Shield® ENV

Strata-Shield® ENV is the ideal packaging for static-sensitive products. Strata-Shield® ENV anti-static material is made with a permanently static dissipative, non-humidity dependent, non-sparking, and amine-free surface, formulated for corrosion control and polycarbonate compatibility.

Strata-Shield® ENV advantages

- superior physical protection of electrostatic discharge (ESD) sensitive materials

- partitions cost less than anti-static bags and require less labor

- abrasion resistant

- recyclable

- stronger and cleaner than other paper materials

- dust resistant

Strata-Shield® ENV is ideal for

- protecting electrostatic discharge (ESD) sensitive materials

- anti-static trays and bins

- anti-static pads

- tote trays

- partition dividers (both solid fiber and corrugated)

- anywhere attracting dust is an issue